Piano Defects and Damages Repaired

Examples of Piano Problems We Have Solved

Sometimes fine pianos, especially from the 1960’s through the 1980’s, have design flaws and workmanship issues that when repaired, will make them better than new. A qualified piano repair or restoration can make these pianos what they were intended to be—fine musical instruments. Other times, we see fine pianos that have been assaulted with shoddy repair and restoration. It’s heart breaking, but we can fix it. Below are just some of the piano repairs we have performed, and examples of violated pianos we have recovered from past abuse.

Images in our Piano Services Gallery can be enlarged by clicking on the image

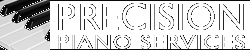

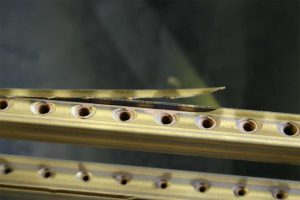

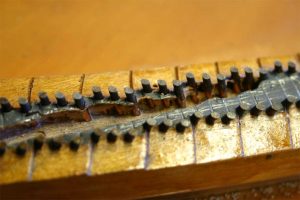

Bridge Notching Defects From Piano Manufacturers

Above, we see examples of horrible piano bridge notching and poor casting on the plate horn from a well known, high end piano manufacturer in the mid 1970’s. This is very typical of the workmanship exhibited in piano manufacturing from the 1960’s through the 1980’s. Thankfully, this kind of substandard quality is becoming MUCH less common as current piano buyers are wary of spending tens of thousands of dollars on poorly made musical instruments.

Replacing the Patented Steinway and Sons Tubular Metallic Action Frame Rails

Many vintage Steinway and Sons grand pianos and upright pianos exhibit cracking and disintegrating of their patented Tubular Metallic Action Frame Rails. These rails shown are beyond repair, and new rails were installed to complete this Steinway piano restoration.

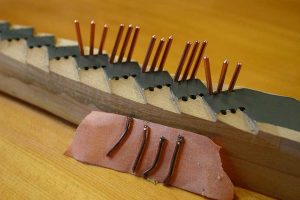

Short-Arm Steinway Teflon Damper Back Action Replacement

Notice the damage to key-end felts above caused by the short-arm damper underlever systems that were used in Steinway pianos from the mid 1940’s through the 1960’s, and even into the early 1980’s when they were further modified using teflon bushings in the 1960’s. The incorrect geometry of these levers force the extension arms to “dig-in” to the backs of the keys, resulting in premature wear of the damper lever lifter felt. Not only does this cause unnecessary friction in the action of the piano that the pianist can feel, but damper efficiency is also compromised due to the lack of proper geometry necessary to make each note silence properly. Sustain pedal “feel” is also negatively affected for the player, due to incorrect damper tray travel.

The only proper solution is to replace the defective tray with a correctly engineered German Renner Damper Tray system, modeled after the original Steinway designed long-underlever system used in vintage Steinway pianos, and, current production pianos.

Improper Piano Refinishing Techniques Ruined This Piano’s Performance

Here is a Steinway Model M that we dismantled and discovered just how badly a prior refinishing attempt ruined the soundboard and bridges of a piano.

You can see the stripping agent that was used seeped down on the edges of the soundboard. They did not remove the plate of the piano and carelessly let it sit on the wood, destroying the finish and fibers of the wood, and loosening the crucial glue holding the soundboard on the rim of the piano.

In fact, no care was taken at all as much of the stripping agent even splattered all the way to the long bridge of the piano, hitting the pins and strings as well.

Improper Piano Refinishing Techniques Also Ruined this Piano’s Performance

Here is a sadly poor refinishing job done in years past on a very rare Steinway and Sons Model C piano. The plate was not removed before refinishing, and the stripping agent was left to bleed into the soundboard area of the piano (first image). Sloppy work can have deleterious effects on the performance of a piano. Shown on the above on the second image, the stripping agent was left to penetrate into the pinblock of the piano. Needless to say, this piano soon afterward became untuneable.

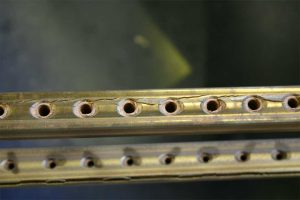

Careless Piano Refinishing with Overspray On a Keybed

This is another example of horrid refinishing techniques on a beautiful Steinway grand piano. The previous refinisher carelessly left the keybed of the piano unmasked, and simply sprayed finish all over the interior of the action cavity. Needless to say, the action made a LOT of noise when the soft shift pedal was applied! The last two pictures show the cleaned and polished keybed, ready for action frame insertion and keyframe leveling. Our completed keybed is finish sanded with 800 Grit sand paper for a glass smooth finish, which reduces drag and noise when the soft shift pedal is used.

2 Year Old Bösendorfer Model 200 Grand Piano Destroyed by Environmental Conditions

Shown in these pictures is a 2 year old Bösendorfer grand piano that was in a home situated in Malibu, CA only a few feet from the coastal shoreline. The owner carelessly left the top of the piano open all the time, with giant sliding glass doors that were open to the sea and salt air every day.

As you can see from theses close up pictures, the painted metal surfaces of the plate appear in good order, but all of the exposed metals…copper bass strings, plain wire, tuning pins, bridge pins and plate bolts all have extremely heavy corrosion.

Not shown is the damage caused to all the brass hardware throughout the cabinetry of the piano, even though lacquer coated for protection, all had signs of corrosion under the coating. The action components internally also suffered from metal corrosion.

Rust is a living disease that continually eats away at exposed metal surfaces. Combine this with actual salt crystals in the moist air of a beach community and it is a recipe for disaster.

These types of situations will never be covered under a factory warranty, and the resulting cost of restoring this type of very expensive piano is a lesson to all to protect your investment as much as possible.

Once we replaced all the affected components of the piano, and cleaned salt and other debris throughout the entire body, a custom made wool string cover and complete damp chaser dry humidity control system was added to the piano to minimize future damage that may take place. The customer was also instructed to keep the lid and fly of the piano completely closed when not in use.

If your piano is located in a home with these extreme conditions, we advise these same precautionary measures.

Piano Bridge Damage Caused by Termites

In a rare case of termite damage, we see the bridge of a 1900 era Steinway and Sons piano upright eaten away by these little creatures. The damage was limited to only the bridge “cap” and did not permeate to the core below. This damage was unknown to us until work began on cleaning the bridge, and the tool we used started to dive past the outer shell of the wood, into the hollow core.

Piano Bridge Drilled and Installed Improperly

Here is a tragic drilling mistake made during production on a very well known, high end semi-concert grand piano built in 1995. This mistake was most likely never reported and apparently hidden by a line worker during the installation of the bridge pins.

The 9 pins in the three center notes demonstrate the correct drilling angle to be used. The two outer notes show the incorrect angles drilled on 4 holes. The pins shown on the tape strip were removed from those very same holes, and clearly show how the pins were installed using the incorrect angle, then BENT at the top to simulate the correct angle! Our best guess is that the worker reversed the drill angle that was supposed to be used on the rear of the bridge, and started drilling that angle incorrectly on the front.

What is most baffling is the fact that it was drilled incorrectly to begin with, then a few notes were drilled properly, and then again drilled incorrectly on the last note! This bridge cap should have been replaced on the line, but sadly, was left to be discovered years later when tonal issues became apparent and the piano was well beyond warranty.

Cheap Repairs and Unqualified Piano Restoration Errors

These pictures illustrate a horrifying soundboard repair performed on a vintage German Steinway and Sons Model O grand piano. Notice the careless use of oversized screws in an attempt to stop buzzing from ribs that detached from the panel of the soundboard. There is even a machine bolt and nut through one of the ribs! This inept type of repair is all too common in today’s quick and cheap wholesale piano rebuilding. Needless to say, this soundboard was made worse than before the attempted “repair.” In order to restore this piano to its former glory, a new, original dimension soundboard was produced and duplicated to the exact standards used by Steinway and Sons at the time the original board was made. When completed, the piano sounded as good as new!

Mason and Hamlin Soundboard Destroyed by Unskilled Repairs

This is a telling example a vintage Mason and Hamlin Model A grand piano soundboard egregiously “repaired” by a piano assaulting thug. These types of mafia repairs will destroy a piano’s integrity, and the potential for buzzing and rattling is increased ten-fold. These types of brute force repairs should NEVER be attempted, and the proper techniques should be left to those qualified and skilled enough to undertake the endeavor. Fortunately, we outfitted this back room interrogated piano with a new, dimensionally duplicated soundboard and all new bridges…restored to its former glory.

We took several pictures for our scrapbook but the selection here gets the point across.

1883 Steinway Model A1 Original Soundboard

This original soundboard on an 1883 Steinway and Sons Model A1 grand piano has been removed from the rim of the piano. Notice how every one of the ribs have detached from the piano and remained on the rim when we removed the board. Immediately noticeable in the second picture is an attempted fix where a “piano technician” in the distant past wedged a large angled shim underneath the #11 uppermost treble rib in an obvious attempt to stop an annoying buzz.

This sometimes will cure a buzzing situation, but at the expense of completely destroying any tone and sustain that the board is designed to provide. Without the ribs firmly attached to the panel, any cracks present will easily separate and cause horrible buzzing and vibration, and only proper repairs can cure this situation. As you can well imagine, there was no such thing as “crown” on this board.

This is a prime example that shows why old soundboards do not stand the test of time, and eventually need to be replaced. This piano’s soundboard was beyond any reasonable repair in this condition, and was replaced with a dimensionally duplicated new soundboard and bridge tops.

Story and Clark Piano Console with So Called “Bridge Repair”

This is an older, American-made Story and Clark console with a very common bass bridge split, and an attempted “repair” of the cap. Actually, this cannot even be considered a repair since the split is still on the cap. The “piano technician” simply loosened the strings, removed the bridge pins, and slid popsicle sticks underneath the strings to elevate them over the crack! Not surprisingly, the tone produced was horrid, and the buzzing on each note was worse than before the modification. Our repair included a brand new bridge cap with pins, and all new bass strings to compliment the proper restoration of this shelf bridge.

Drilling a New Piano Pinblock

Notice the air nozzle used to cool the drill bit as the new piano pinblock is drilled. Drill speed selection and accuracy are crucial in maintaining uniformity of the drilled holes, and stable tuning pin torque on the restored piano. We also see the new pinblock versus the old pinblock. An exact duplicate of your piano’s pinblock must be produced to achieve the best results.

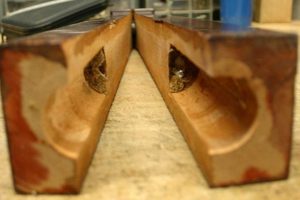

Repairing Broken Piano Legs and Other Broken Piano Parts

This piano leg split in two pieces as piano movers tried to set the piano back up on its feet. Notice the clean break along the glue joint up the center of the leg. Weak glue joints can have disastrous effects if no one is aware of them! Precision Piano Services will inspect for these kinds of weaknesses during a piano restoration.

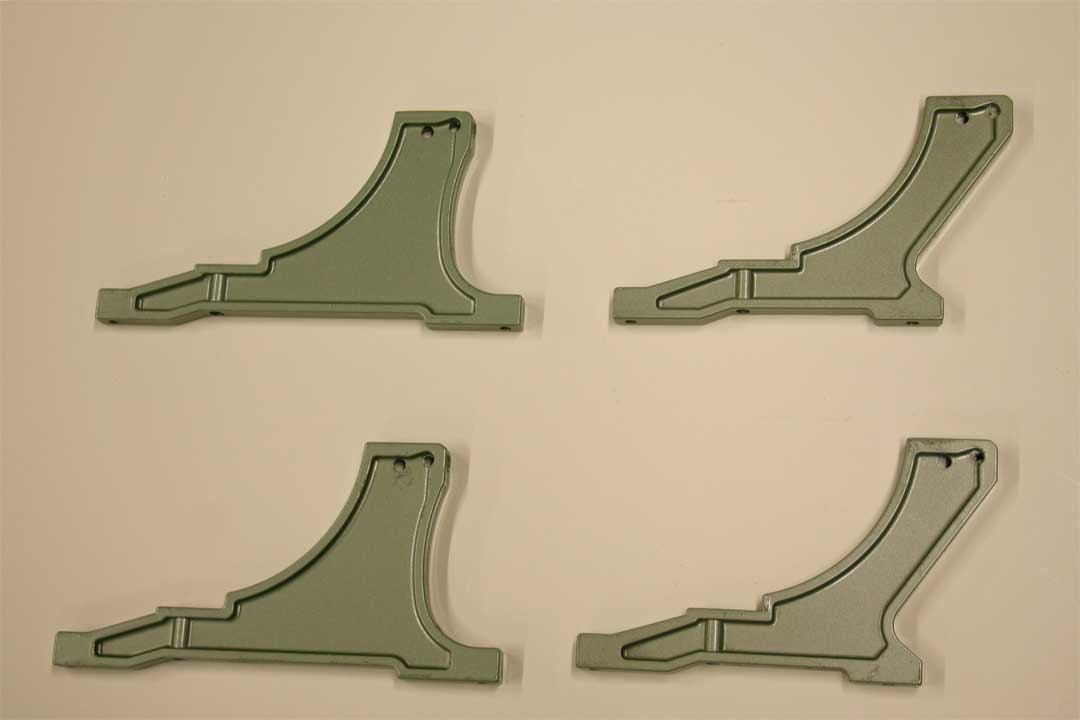

Manufacturer Warranty Repairs

Here we see four brackets that hold together the stack (or frame) of a current production Korean made piano action. These piano brackets produced through the 1980’s and 1990’s, have a tendency to “grow” or expand, causing the action to go out of regulation. The only solution is to retrofit the brackets with new stable material, and re-regulate the action. This has been part of some the warranty repairs we have performed for many piano makers.