Steinway and Sons Piano Restoration

Restoring the World’s Most Famous Piano

Images in our Piano Services Gallery can be enlarged by clicking on the image

Identifying Your Steinway and Sons Piano

These pictures illustrate where to look for the Serial and Model Number and Part Number for your Steinway and Sons grand piano. These numbers can be easily identified on the plate, underneath the music rack (which simply slides out of the piano). If the numbers are not on your Steinway, it has more than likely been refinished and carelessly left off the instrument by the refinisher. Not to worry—Part Numbers and Serial Numbers are in multiple places on Steinway instruments—it will just take a little more effort to find them! The word “Ebonized” indicates that the piano was destined to have a black finish.

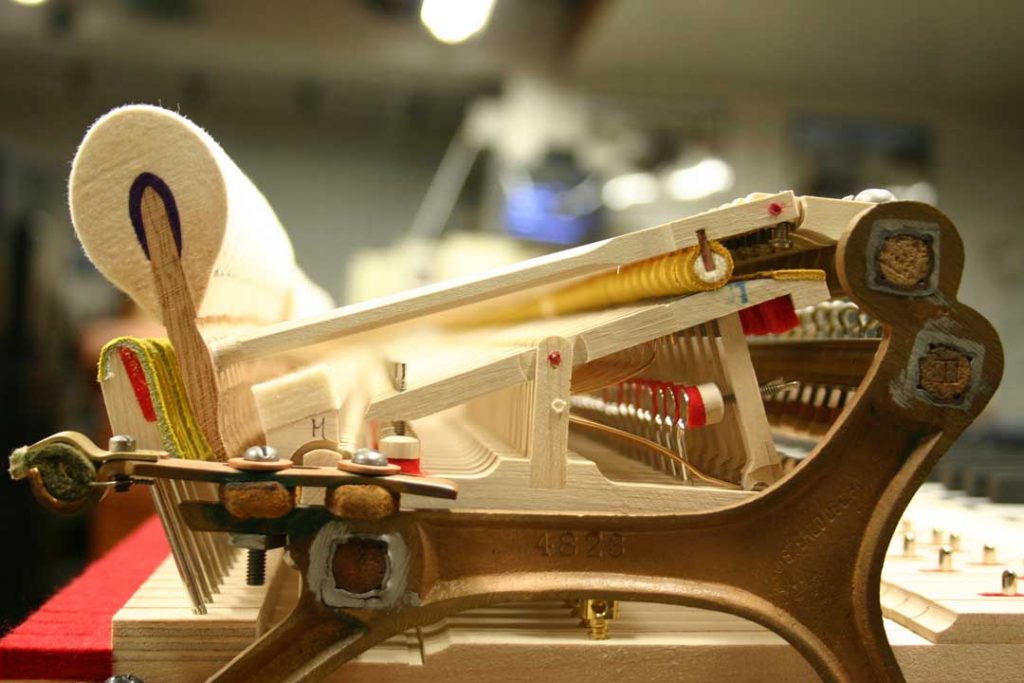

Patented Steinway and Sons Grand Action

Here we see a side view of the famous, patented Steinway and Sons grand action. Notice the 3 tubular metallic action rails that hold the flanges and let-off buttons in place. Steinway has used this type of action frame for well over 100 years. New Renner action parts and hammers are installed, and this “stack” sits atop a brand new spruce keyset. The ultimate in piano action restoration!

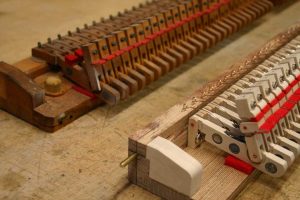

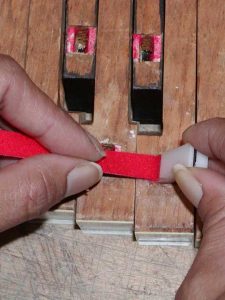

Renner Damper Back Action Replacement

Here are pictures of a Renner damper tray replacement, completed and ready for installation into a Steinway grand piano. Renner replacement tray duplicates Steinway’s original, and most desired, tray configuration (the “long-arm” underlever), which enables us to use the exact geometry necessary to achieve the best in damper system performance. Additionally, this also allows us to replace the myriad of Teflon® era damper systems out there that have the geometrically incorrect “short-arm” levers which contribute to poor damper performance, poor pedal performance, and premature key-end felt wear. The damper system is also one of the most overlooked components in the wholesale piano restoration business today.

Bead Blast Cleaning of Steinway and Sons Piano Action Stack to Remove Corrosion

The finest glass beads available are used in our sandblasting cabinet (which can house an entire concert grand action), to remove years of corrosion and dirt. Notice the screws for the piano action parts are installed not only to clean them, but to prevent the glass beads from clogging the rails.

1883 Steinway Model A1 Original Soundboard

This original soundboard on an 1883 Steinway and Sons Model A1 grand piano has been removed from the rim of the piano. Notice how every one of the ribs have detached from the piano and remained on the rim when we removed the board. Immediately noticeable in the second picture is an attempted fix where a “piano technician” in the distant past wedged a large angled shim underneath the #11 uppermost treble rib in an obvious attempt to stop an annoying buzz.

This sometimes will cure a buzzing situation, but at the expense of completely destroying any tone and sustain that the board is designed to provide. Without the ribs firmly attached to the panel, any cracks present will easily separate and cause horrible buzzing and vibration, and only proper repairs can cure this situation. As you can well imagine, there was no such thing as “crown” on this board.

This is a prime example that shows why old soundboards do not stand the test of time, and eventually need to be replaced. This piano’s soundboard was beyond any reasonable repair in this condition, and was replaced with a dimensionally duplicated new soundboard and bridge tops.

Steinway and Sons Early Front Duplex Bearing Bars

Notice that each note on these Steinway and Sons early front duplex bearing bars has an individual rest located in precisely the correct position. The last picture shows Steinway’s later design change to generic slanted bars that are still used to this day.

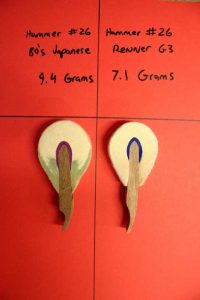

Piano Hammer Action Components – Using Genuine Renner Replacement Parts

One of the most common and major problems in piano action rebuilding today is the incorrect use of heavy hammers in vintage Steinway pianos. The Japanese hammers that were used predominantly in the 1980’s, are substantially heavier than the current special order Premium Renner Blue Hammers that we use on most vintage Steinway and Sons pianos.

The most significant problem visible in this example is at note #26 (center photo), where we see the Japanese hammer is 2.3 grams heavier than the Renner replacement. Understanding that each gram at the hammer end of the shank increases touch-weight by 5 grams at the key, the Japanese hammer would make note #26 about 12 grams heavier to the touch! Amplify this with incorrect parts selection that have geometry problems, and it is easy to see how an inexperienced technician can ruin the performance of a Steinway piano action.

It is not uncommon for us to see poorly restored Steinway piano actions with down-weight measurements of 90 grams, and up-weight measurements of as low as 10 grams. In addition to that, many technicians will try to compensate for these poor performance numbers by inserting 6, 7, or sometimes even 8 leads in a desperate attempt to improve the touch of the piano. This is futile exercise that only makes the situation worse.

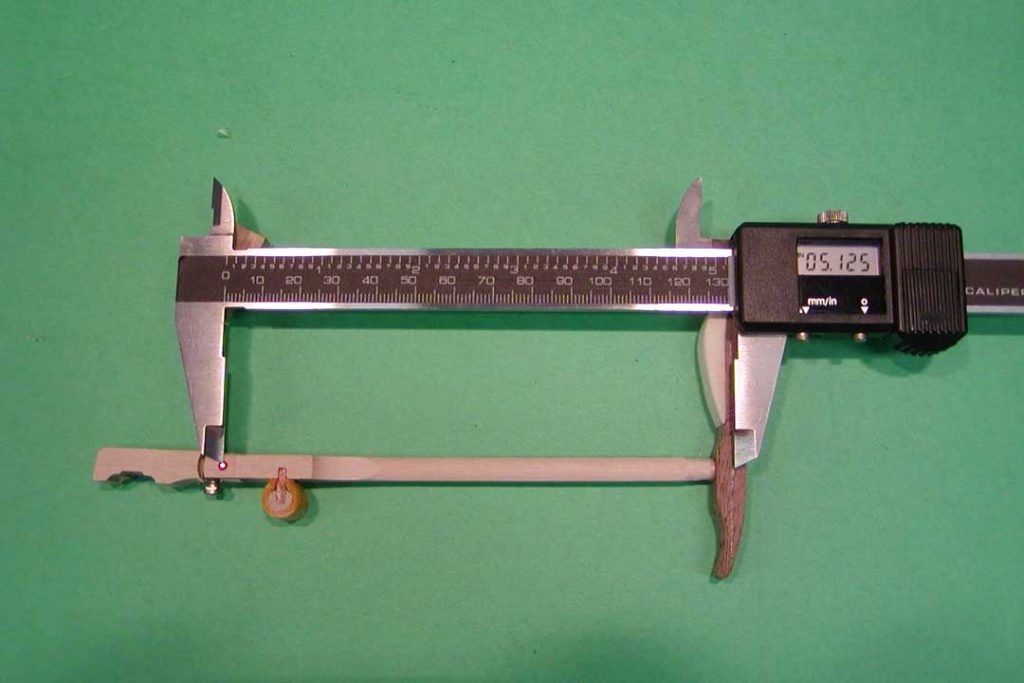

Steinway and Sons Piano Hammer Placement

Current Steinway and Sons piano specifications call for the hammers to be hung on the shank at 51/8“. Vintage Steinway actions have hammers that are hung anywhere from 5” to 51/16” on the shank. Here, a 1/8″ difference would be drastic if not corrected properly! In fact, the last few upper octaves of the piano are the most crucial for hammer placement. Our hammers are hung according to the best possible sound produced, in relation to the optimal placement of the action fore and aft. “Pre-hung” hammers on shanks available from the factory do not work properly in most older Steinway and Sons pianos.

Vintage Steinway Pianos and Verdigris

For years on early vintage Steinways, the action parts were dipped in a paraffin oil to act as a preservative for the wood. This accounts for the dark color of vintage Steinway parts. A drawback of the dipping solution is the chemical reaction with the centerpins and all the moving parts, resulting in what is known as Verdigris. This Verdigris gums up on the centerpins and felt (the green patina shown in the close-up), and results in sluggish action parts. This is one of the most major problems with older Steinway pianos. There are no permanent fixes for this condition other than replacing the defective components with new parts.

Replacing the Agraffes Is Standard Procedure When We Rebuild Steinway Pianos

All of our rebuilt Steinway and Sons pianos will include replacing the agraffes. Agraffes are made of brass, and if they have been over-torqued at the factory, they will eventually break. This will take 70 years sometimes, but it will happen! Nonetheless, new clean agraffes not only look nice, but contribute to better tone in the piano. The steel wire that goes through the agraffes is harder than the brass, so it will eventually deform the round holes making them oval.

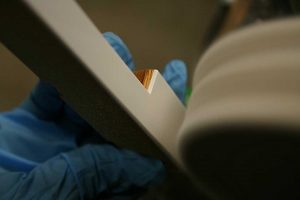

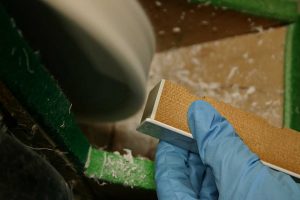

Filing of the Capo D’Astro Bar When Restoring Pianos

Along with replacement of the agraffes, capo bar filing is essential to remove old string grooves, and to make sure the profile of the bar is at its optimal shape. This is one of the most overlooked steps in the “wholesale piano rebuilding” end of this industry.

Accurately Reproduced Vintage Steinway Hammer-Butt Replacements

Here we see a replacement hammer-butt for a vintage Steinway upright (above right). Imadegawa Company of Japan is currently the most accurate reproducer of this hard to find component. Even the damper levers and wippens are reproduced to the exact dimension needed in order to insure a proper feel and action response. Vintage Steinway upright pianos excel when these components are used to restore the action of the piano. Abel hammer samples prehung at each end section are shown above left.

1929 Steinway Video Showing How Steinway Pianos Were Made

This interesting, historical film shows the process of producing hand-made Steinway and Sons pianos at their New York factory. It even features the piano music of Scott Joplin.

This is an unused marketing video produced by the Steinway Company in 1929 displaying how they manufacture their Style B Grand Piano. Most of the techniques have stayed the same in the 80 year interim.

For more on Steinway, check out these La Guardia and Wagner Archives where you will find a rich collection of photographs and documents about Steinway and New York City’s history.

Enjoy this brief bit of history to further your appreciation of vintage Steinway and Sons pianos.